End Mills

Follow us on

Special End Mills Geometries for Diverse Applications

Our End mills are designed for high-speed machining, enabling faster production times while maintaining quality and precision.

Special End Mills Geometries by GTW

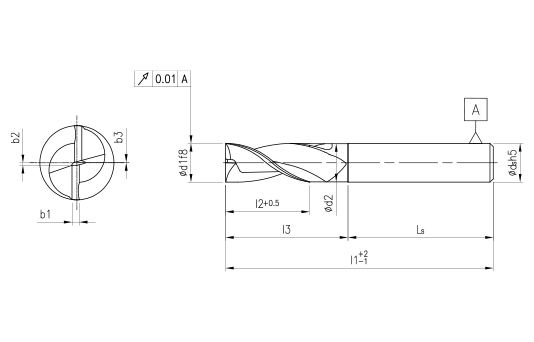

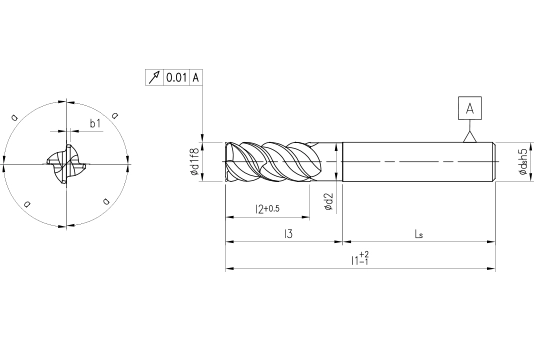

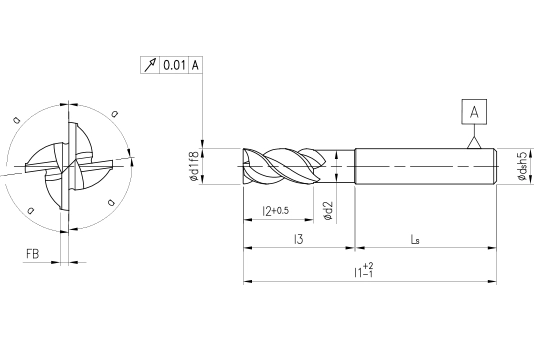

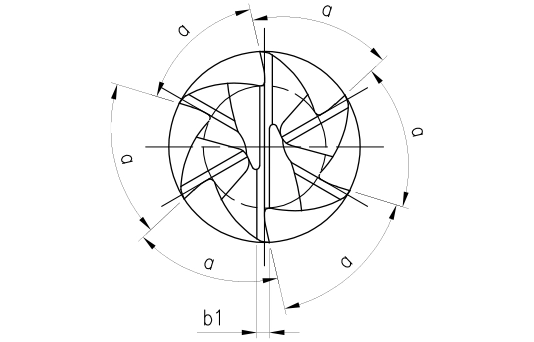

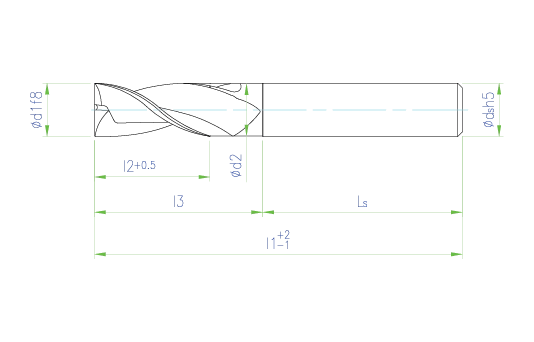

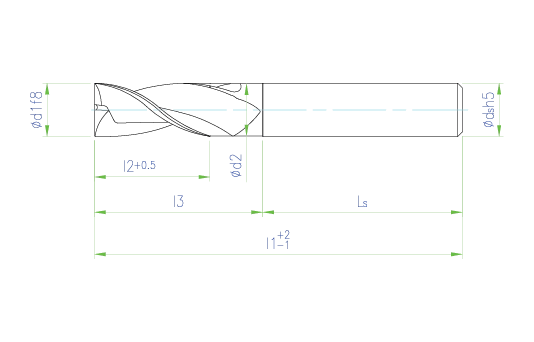

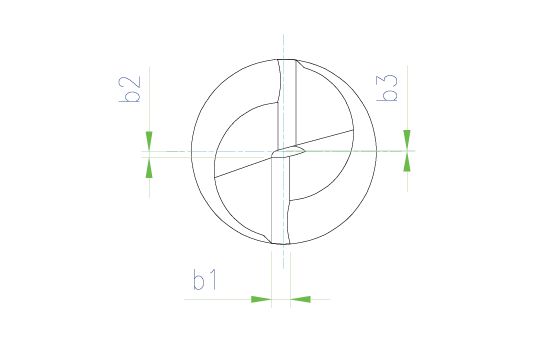

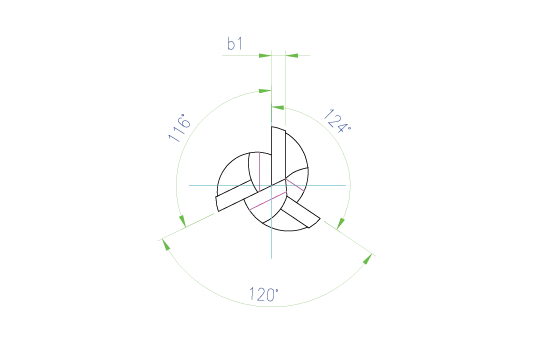

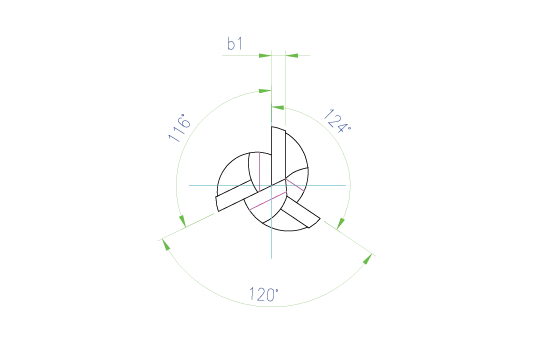

Features of GTFM 2240 GEOMETRY

| 02 Spiral flute |

| 01 Cutting edges over centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 4 |

| Diameter Range – 1mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 2240 GEOMETRY

| 1.1.1 | Free Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Constructional Steel |

| 1.2.2 | |

| 1.2.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |

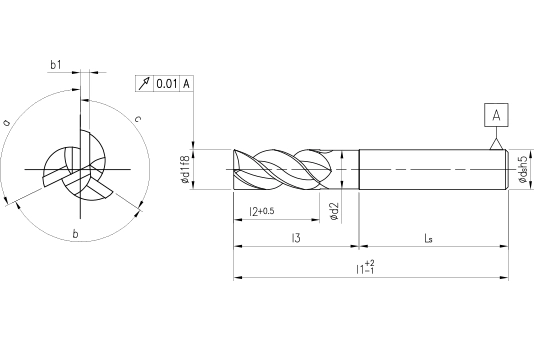

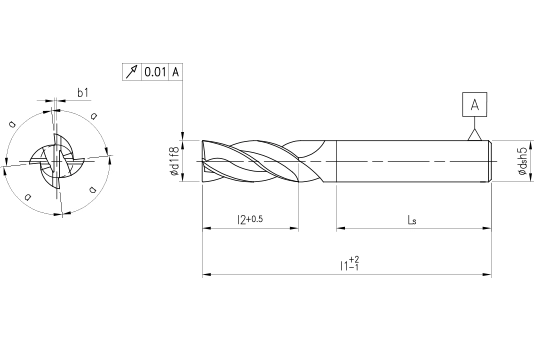

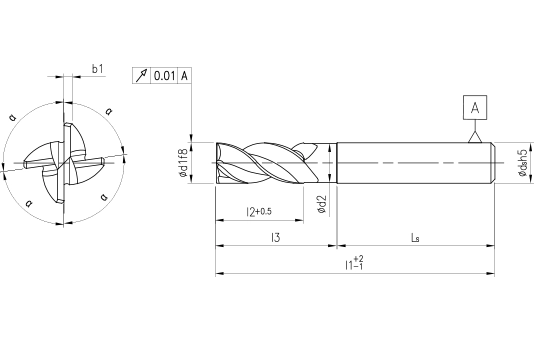

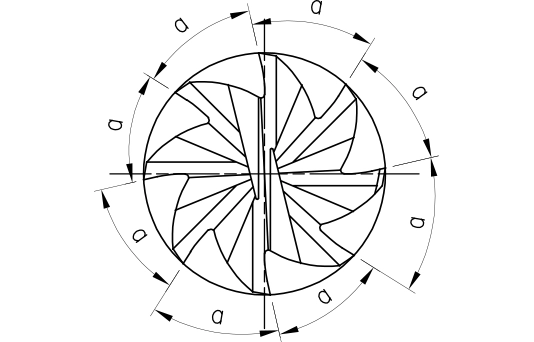

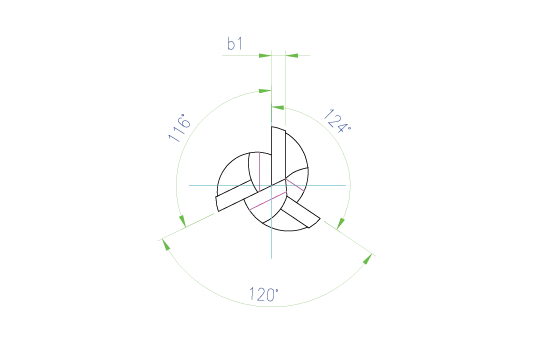

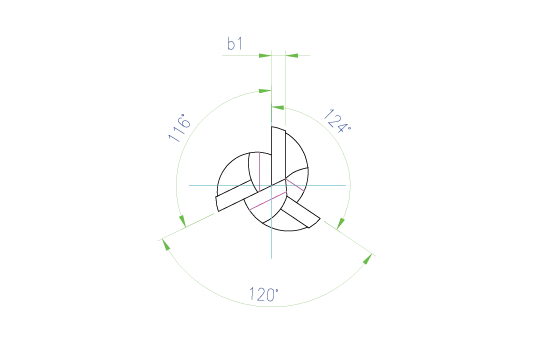

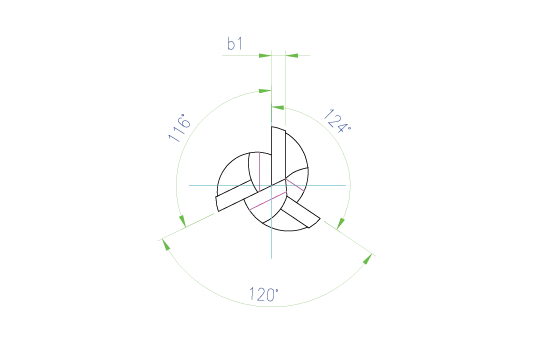

GTFM 3950 GEOMETRY

| 03 Spiral flute |

| 01 Cutting edges over centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 4 |

| Diameter Range – 4mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 3950 GEOMETRY

| 1.1.1 | Free Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Constructional Steel |

| 1.2.2 | |

| 1.2.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |

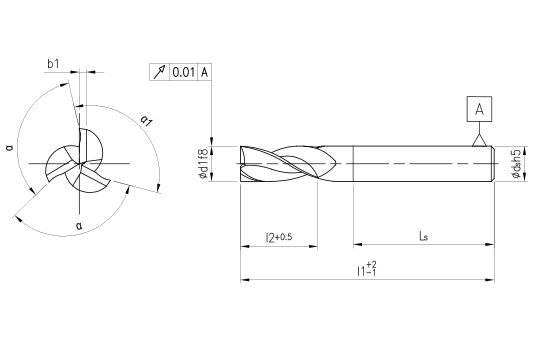

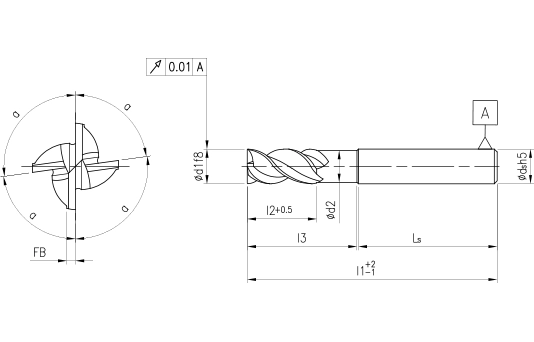

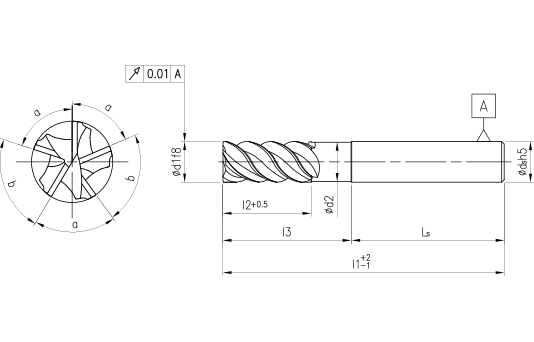

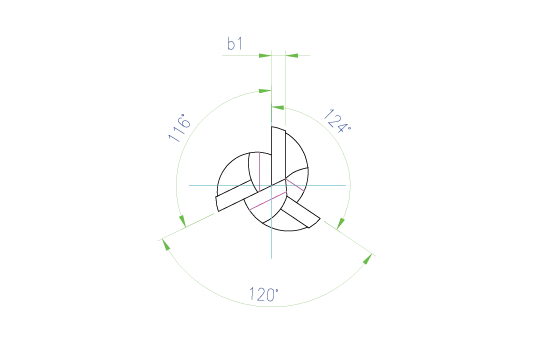

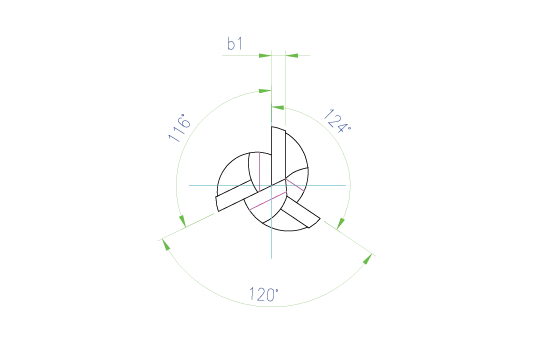

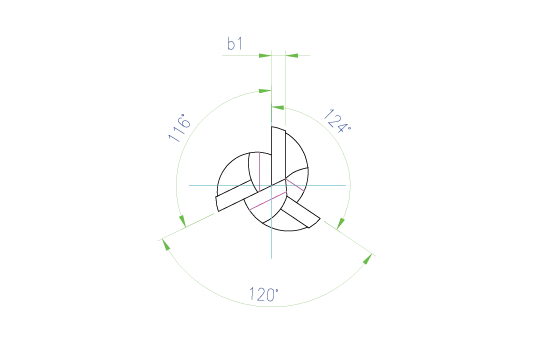

Features of GTFM 3240 Geometry

| 03 Spiral flute |

| 01 Cutting edges over centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 3mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 3240 GEOMETRY

| 1.1.1 | Free Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Constructional Steel |

| 1.2.2 | |

| 1.2.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |

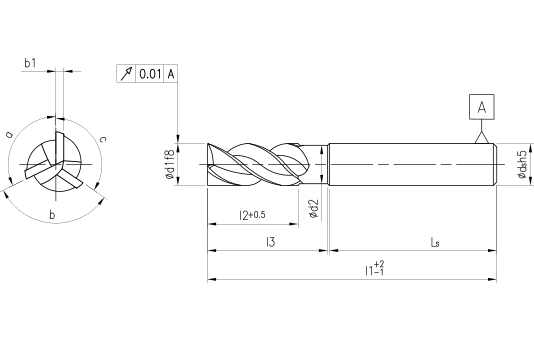

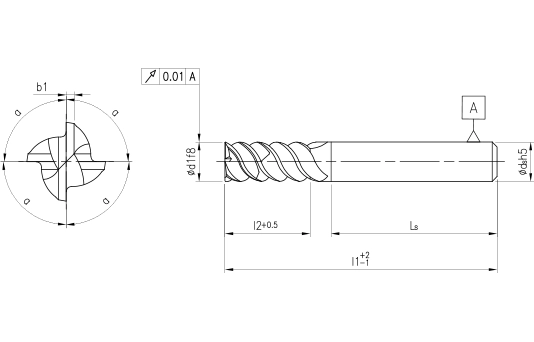

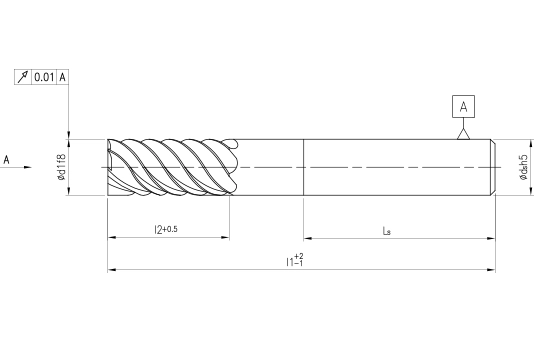

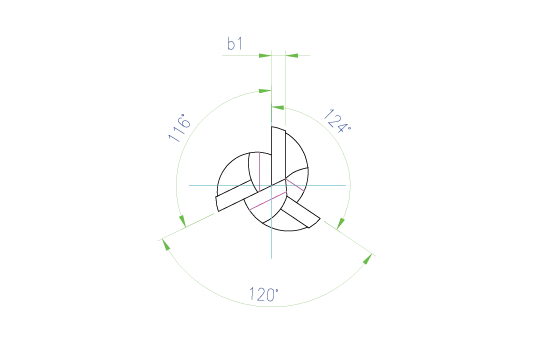

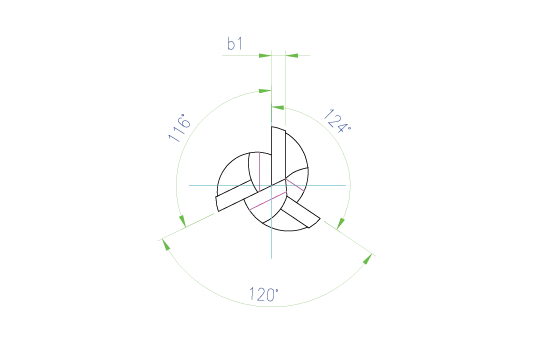

Features of GTFM 3350 Geometry

| 03 Spiral flute. |

| 01 Cutting edges over centre. |

| Right hand cut. |

| without internal coolant holes. |

| L/D Ratio – Up to 3. |

| Diameter Range – 3mm to 20mm. |

| PVD Coated – As per application. |

| Cylindrical Shank – DIN 6535 HA/HB/HE. |

Application Material for GTFM 3350 GEOMETRY

| 7.1.1 | Aluminium |

|---|---|

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 |

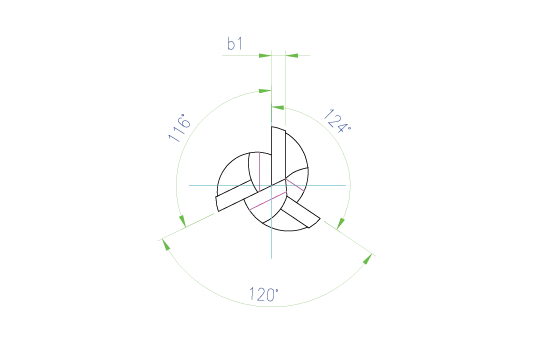

Features of GTFM 4910 Geometry

| 04 Spiral flute. |

| Reduced cutting force. |

| Right hand cut. |

| without internal coolant holes. |

| L/D Ratio – Up to 3. |

| Diameter Range – 4mm to 20mm. |

| PVD Coated – As per application. |

| Cylindrical Shank – DIN 6535 HA/HB/HE. |

Application Material for GTFM 4910 GEOMETRY

| 1.3.1 | Spring Steel |

|---|---|

| 1.3.2 | |

| 1.3.3 | |

| 2.2.2 | Nitriding Steel |

| 2.3.4 | Tempered Steel |

| 2.3.5 | |

| 2.3.6 | |

| 3.2.1 | Tool Steel for Cold Working |

| 3.2.2 | |

| 3.2.3 | |

| 3.2.4 | |

| 3.2.5 | |

| 3.3.1 | Tool Steel for Hot Working |

| 3.3.2 | |

| 3.3.3 | |

| 3.3.4 | |

| 3.3.5 | |

| 3.5.1 | Tempered Tool Steel |

| 3.5.2 | |

| 3.5.3 |

Features of GTFM 4240 Geometry

| 04 Spiral flute |

| Reduced cutting force |

| 02 cutting edges cutting to the centre |

| Linear relief angle |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 2mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 4240 GEOMETRY

| 2.2.1 | Nitriding Steel |

|---|---|

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 |

Features of GTFM 4350 Geometry

| 04 Spiral flute |

| Reduced cutting force |

| 02 cutting edges cutting over centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 3mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 4350 GEOMETRY

| 7.1.1 | Aluminium |

|---|---|

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 |

Features of GTFM 4940 Geometry

| 04 Spiral flute |

| 02 cutting edge to centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 4mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 4940 GEOMETRY

| 1.3.1 | Spring Steel |

|---|---|

| 1.3.2 | |

| 1.3.3 | |

| 2.2.2 | Nitriding Steel |

| 2.3.4 | Tempered Steel |

| 2.3.5 | |

| 2.3.6 | |

| 3.2.1 | Tool Steel For Cold Working |

| 3.2.2 | |

| 3.2.3 | |

| 3.2.4 | |

| 3.2.5 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 3.3.3 | |

| 3.3.4 | |

| 3.3.5 | |

| 3.5.1 | Tempered Tool Steel |

Features of GTFM 4950 Geometry

| 04 Spiral flute |

| 02 cutting edge to the centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 3mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 4950 GEOMETRY

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Constructional Steel |

| 1.2.2 | |

| 1.2.3 | |

| 1.3.1 | Spring Steel |

| 1.3.2 | |

| 1.3.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 3.1.1 | Unalloyed Tool Steel |

| 3.2.1 | Tool Steel For Cold Working |

| 3.2.2 | |

| 3.2.3 | |

| 3.2.4 | |

| 3.2.5 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 3.3.3 | |

| 3.3.4 | |

| 3.3.5 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 |

Features of GTFM 4960 Geometry

| 04 Spiral flute |

| 02 cutting edge to the centre |

| Right hand cut |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 3mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 4960 GEOMETRY

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Construction Steel |

| 1.2.2 | |

| 1.2.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 3.1.1 | Unalloyed Tool Steel |

| 3.2.1 | |

| 3.2.2 | Tool Steel For Cold Working |

| 3.2.3 | |

| 3.2.4 | |

| 3.2.5 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 3.3.3 | |

| 3.3.4 | |

| 3.3.5 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |

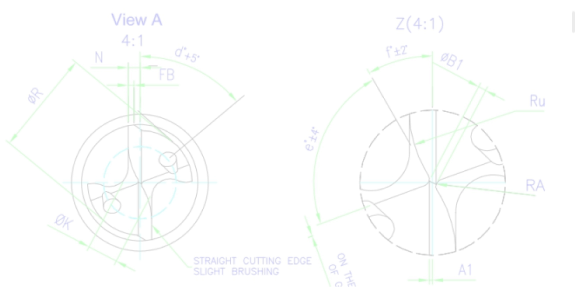

Features of GTFM 5950 Geometry

| 05 Spiral flute. |

| 02 cutting edge to the centre. |

| Straight cutting edge. |

| Right hand cut. |

| Increased metal removal rate. |

| Irregular pitch. |

| without internal coolant holes. |

| L/D Ratio – Up to 3. |

| Diameter Range – 3mm to 20mm. |

| PVD Coated – As per application. |

| Cylindrical Shank – DIN 6535 HA/HB/HE. |

Application Material for GTFM 5950 GEOMETRY

| 4.1.1 | Stainless Steel |

|---|---|

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |

Features of GTFM 6250 Geometry

| 06 or 08 Spiral flute |

| 02 cutting edges to the centre |

| excellent surface finish and precision |

| Right hand cut |

| High metal removal rate |

| Ideal for high-speed milling operations |

| without internal coolant holes |

| L/D Ratio – Up to 3 |

| Diameter Range – 3mm to 20mm |

| PVD Coated – As per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for GTFM 6250 GEOMETRY

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Construction Steel |

| 1.2.2 | |

| 1.2.3 | |

| 2.1.1 | Cementation Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.4 | |

| 4.1.5 | |

| 4.2.1 | Heat Resistant Alloys |

| 4.2.2 | |

| 4.2.3 | |

| 4.2.4 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.1 | Stainless Cast Steel |

| 5.2.2 | |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.1.4 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.3.4 | |

| 7.3.5 | |

| 7.3.6 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.6.1 | CuAlFe (Ampco) |

| 7.6.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 |