Reamers

Follow us on

Special Reamers Geometries for Diverse Applications

Our Reamers Manufactured with tight tolerances,ensure precision in every cut, making them perfect for intricate and high-precision operations.

Special Reamers Geometries by GTW

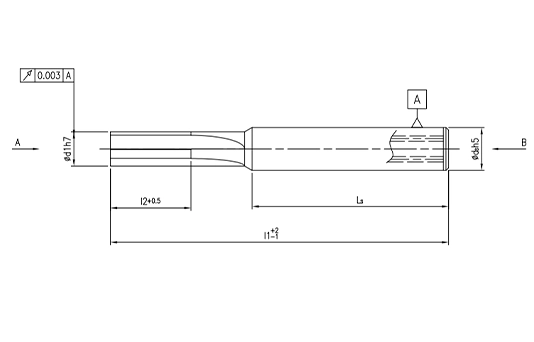

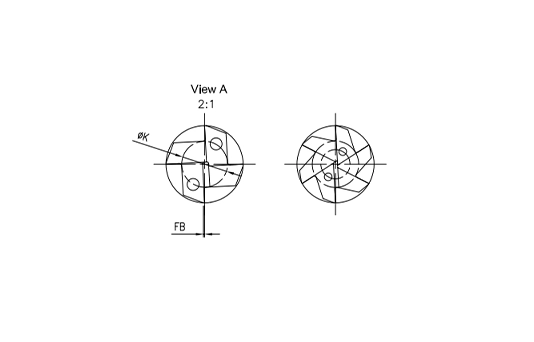

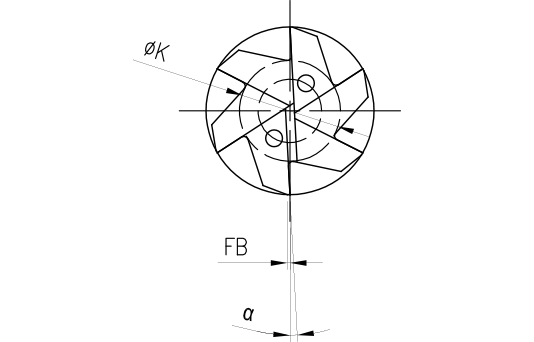

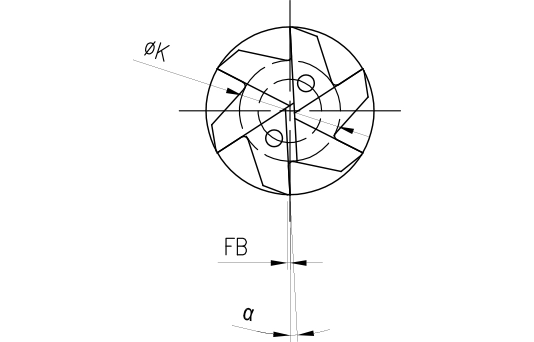

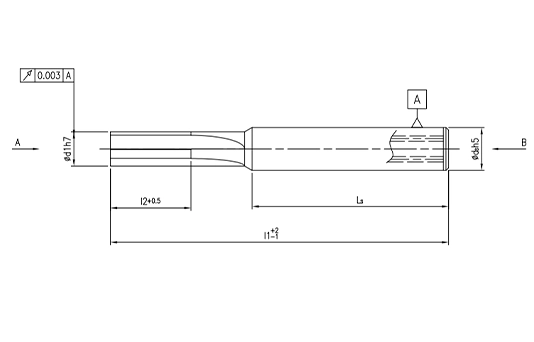

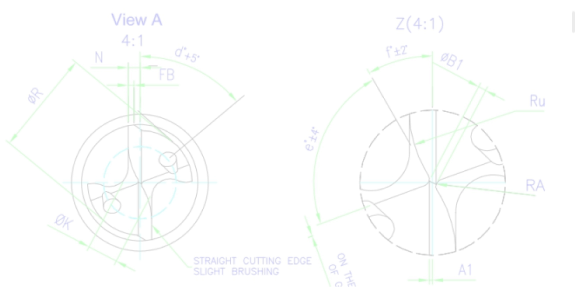

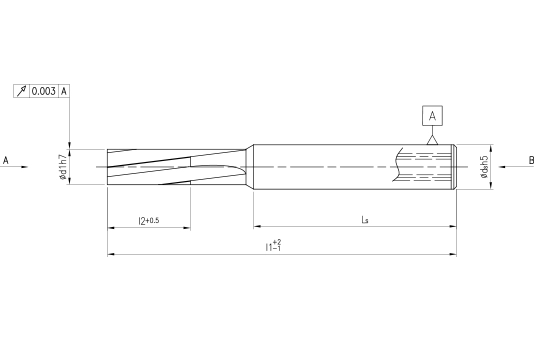

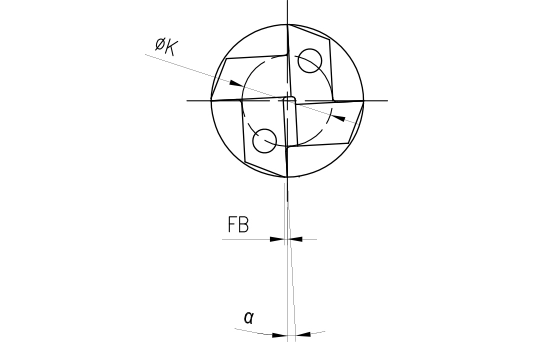

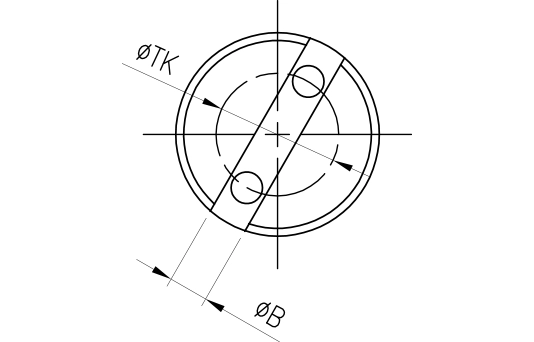

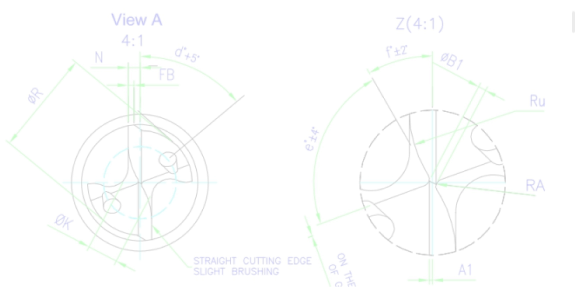

Features of 9R0 Geometry

| Straight or RH spiral or LH spiral fluted. |

| Right hand cut. |

| 02 or 04 or 06 fluted. |

| Enlarge and finish drilled holes to accurate dimensions. |

| Improve the hole's surface finish and achieve a precise diameter. |

| With and without internal coolants. |

| Single margin |

| L/D Ratio – Up to 5 |

| Diameter Range – 2mm to 20mm |

| With or Without Face cutting. |

| PVD Coated – as per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for 9R0 Geometry

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Construction Steel |

| 1.2.2 | |

| 1.2.3 | |

| 1.3.1 | Spring Steel |

| 1.3.2 | |

| 2.1.1 | Case Hardening Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 3.1.1 | Unalloyed Tool Steel |

| 3.2.1 | Tool Steel For Cold Working |

| 3.2.2 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.5 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.2 | Stainless Cast Steel |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 | |

| 8.1.1 | Thermoplast |

| 8.2.1 | Duroplast |

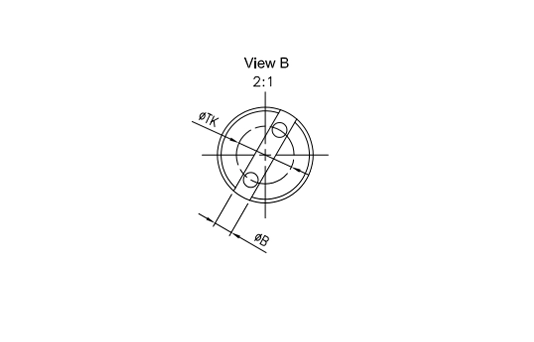

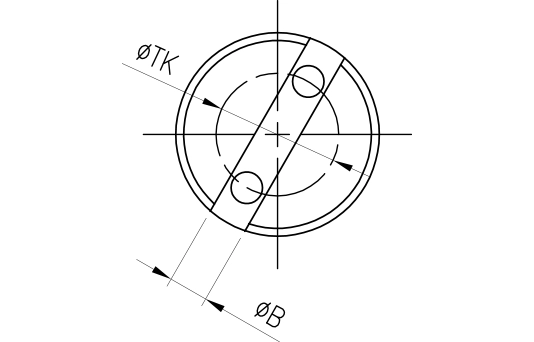

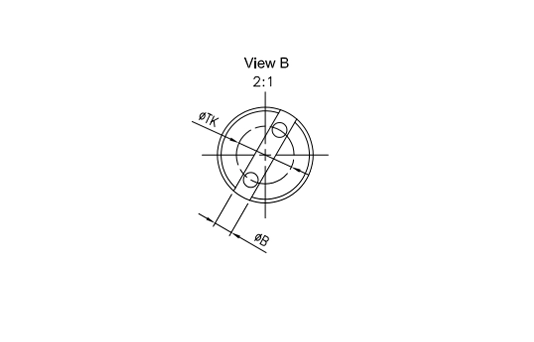

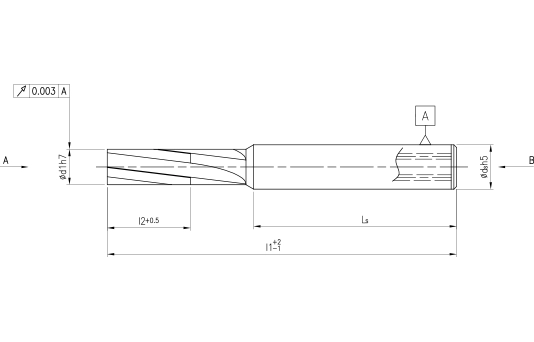

Features of 9R1 Geometry

| LH spiral fluted |

| Right hand cut |

| 02 or 04 or 06 flutes |

| Suitable for thru bore application |

| Enlarge and finish drilled holes to accurate dimensions. |

| Evenly distribute the cutting forces |

| Perform both radial and axial cutting |

| Improve the hole's surface finish and achieve a precise diameter |

| Faster material removal and cleaner hole |

| With and without internal coolants |

| Single margin |

| L/D Ratio – Up to 5 |

| Diameter Range – 2mm to 20mm |

| With or Without Face cutting. |

| PVD Coated – as per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for 9R1 Geometry

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Construction Steel |

| 1.2.2 | |

| 1.2.3 | |

| 1.3.1 | Spring Steel |

| 1.3.2 | |

| 2.1.1 | Case Hardening Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 3.1.1 | Unalloyed Tool Steel |

| 3.2.1 | Tool Steel For Cold Working |

| 3.2.2 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.5 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.2 | Stainless Cast Steel |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 7.1.1 | Aluminium |

| 7.1.2 | |

| 7.1.3 | |

| 7.1.4 | |

| 7.1.5 | |

| 7.1.6 | |

| 7.2.1 | Magnesium |

| 7.2.2 | |

| 7.3.1 | Copper |

| 7.3.2 | |

| 7.3.3 | |

| 7.4.1 | CnZn (Brass) |

| 7.4.2 | |

| 7.5.1 | CuSn (Bronze) |

| 7.5.2 | |

| 7.8.1 | Titanium |

| 7.8.2 | |

| 7.8.3 | |

| 8.1.1 | Thermoplast |

| 8.2.1 | Duroplast |

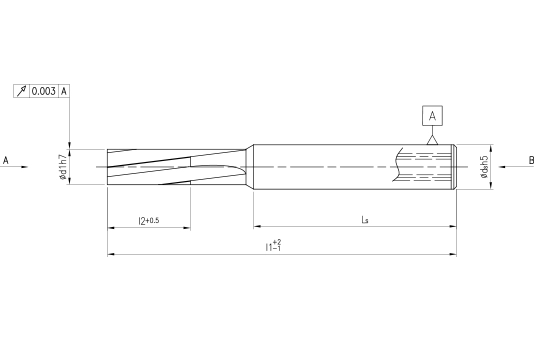

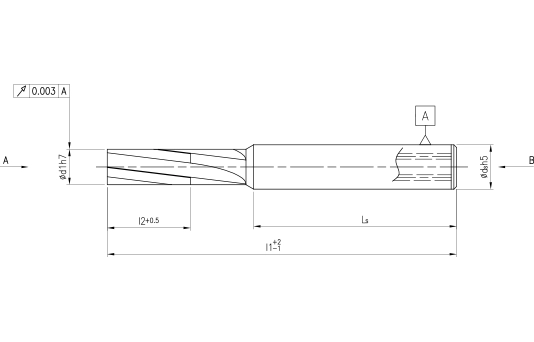

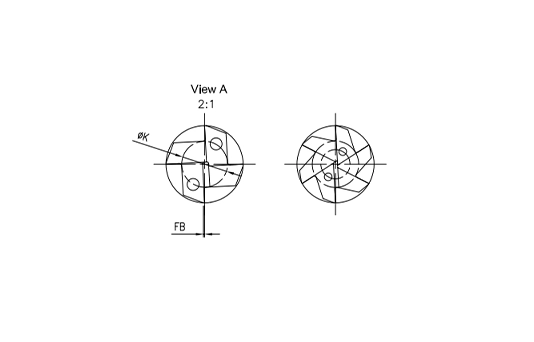

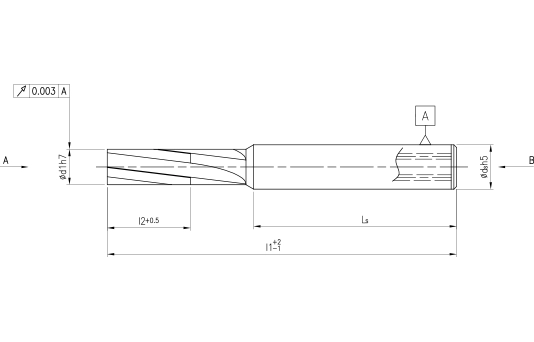

Features of 9R8 Geometry

| RH spiral fluted |

| Right hand cut |

| 02 or 04 or 06 flutes |

| Suitable for blind bore application |

| Enlarge and finish drilled holes to accurate dimensions |

| Excellent at producing smooth, accurate hole surfaces |

| Reduce friction and improve heat resistance |

| With and without internal coolants |

| Single margin |

| L/D Ratio – Up to 6 |

| Diameter Range – 2 mm to 20mm |

| With Face cutting up to center |

| PVD Coated – as per application |

| Cylindrical Shank – DIN 6535 HA/HB/HE |

Application Material for 9R8 Geometry

| 1.1.1 | Machining Steel |

|---|---|

| 1.1.2 | |

| 1.2.1 | Construction Steel |

| 1.2.2 | |

| 1.2.3 | |

| 1.3.1 | Spring Steel |

| 1.3.2 | |

| 2.1.1 | Case Hardening Steel |

| 2.1.2 | |

| 2.1.3 | |

| 2.2.1 | Nitriding Steel |

| 2.2.2 | |

| 2.3.1 | Tempered Steel |

| 2.3.2 | |

| 2.3.3 | |

| 2.3.4 | |

| 2.3.5 | |

| 2.3.6 | |

| 3.1.1 | Unalloyed Tool Steel |

| 3.2.1 | Tool Steel For Cold Working |

| 3.2.2 | |

| 3.3.1 | Tool Steel For Hot Working |

| 3.3.2 | |

| 4.1.1 | Stainless Steel |

| 4.1.2 | |

| 4.1.3 | |

| 4.1.5 | |

| 5.1.1 | Conventional Cast Steel |

| 5.1.2 | |

| 5.1.3 | |

| 5.2.2 | Stainless Cast Steel |

| 6.1.1 | Lamellar Graphite Cast Iron |

| 6.1.2 | |

| 6.1.3 | |

| 6.2.1 | Spheroidal Cast Iron |

| 6.2.2 | |

| 6.2.3 | |

| 6.3.1 | White Malleable Cast Iron |

| 6.3.2 | |

| 6.4.1 | Black Malleable Cast Iron |

| 6.4.2 | |

| 8.1.1 | Thermoplast |

| 8.2.1 | Duroplast |